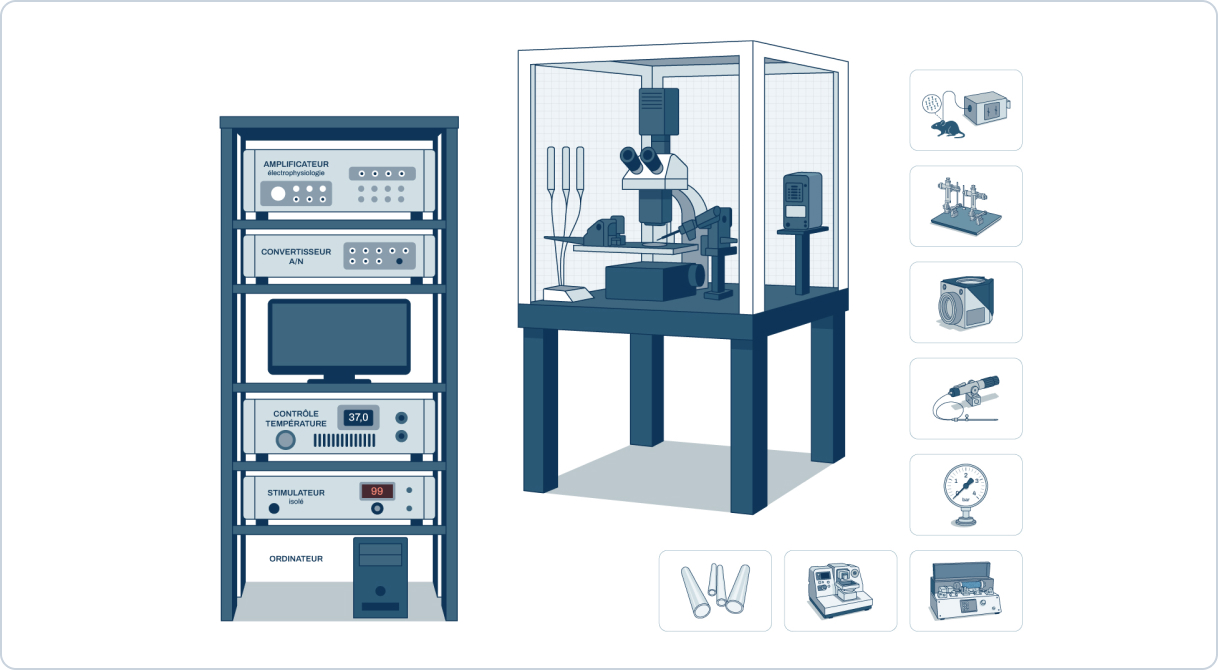

MPC-325 multi-handling system

The MPC-325 is a multi-manipulator system comprising an MPC-200 controller, a Rotary Optical Encoder (ROE) and 1 or 2 MP-225 micromanipulators. Each manipulator offers 3 motorised axes with 25 mm travel and a 4th virtual diagonal axis programmable via DIP switches, without the need for an external computer. The system is stable with very low drift (<0.5 µm/20 h), has sub-micrometer resolution down to 62.5 nm for fine movements and incorporates an accelerated manual mode for fast movements. The user-friendly interface provides easy access to all functions, including HOME and WORK for quick pipette/microelectrode repositioning, and a display of X, Y, Z coordinates and the active manipulator. The MPC-325 can be expanded to control up to 4 manipulators via a second controller.

MPC-325 multi-handling system features

- 3-axis joysticks with 25 mm travel

- 4th virtual diagonal axis programmable via DIP switches

- Low drift: <0.5 µm/20 h

- Sub-micrometer resolution: 62.5 nm for fine movements

- Silent electronics, optimised for per-channel recording

- One controller and ROE drive 2 manipulators; up to 4 manipulators with a second controller

- User-friendly interface with single-button access to all functions

- Moves in 6 increments (0.0625; 0.025; 0.25; 1.0; 2.0 µm)

- HOME and WORK positions for quick pipette/microelectrode exchange

- Accelerated manual mode for fast movements

- Display of X, Y, Z coordinates and active manipulator

- Simple USB interface

- Rocker switch to select the connected manipulator

- Maximum speed: <0.5 µm/24 h

- Dimensions / weight MPC-200 manipulator: 40 cm x 27.3 cm x 9 cm / 3 kg

- Dimensions/weight MPC-200 ROE : 25 cm x 15 cm x 23 cm / 1.6 kg